Odoo Manufacturing Customization

Today the manufacturing sector is facing many challenges due to increased globalization. Globalization has brought an intense competition in the current business scenario, it becomes so hard to manage tasks and attain a talented workforce and retain them as well. Furthermore, handling the cost of the production is really a major factor in the success of the business. Also, constantly changing customers demands makes it difficult to maintain the bottom-line effectively.

Requirement fulfillment

Automatically create procurement orders for raw materials which are defined on BoM. Now, you are able to configure each raw material Product with Make to Order so this will create a Purchase Order for a supplier, but if you install the app: purchase requisition, this will let you receive multiple requisitions and then choose the best supplier based on that. Also, you can choose the best-suited supplier for the operations.

Procurement Order

Generate procurement orders for each supplier. It allows you to obtain raw material as per the manufacturing order and you can keep a clear record of material and related supplier. Requirement fulfillment will end up re-using a certified module which will reduce future migration efforts (easy migration) and maintainability (customized code maintainability) will reduce.

Equipment Maintenance

To manage equipment used in businesses, the Odoo equipment management software was created. Throughout the entire equipment management process, our specialists will be at your side, monitoring everything from repairs to maintenance. Your sales and profitability might go up with the right Odoo equipment management software solution.

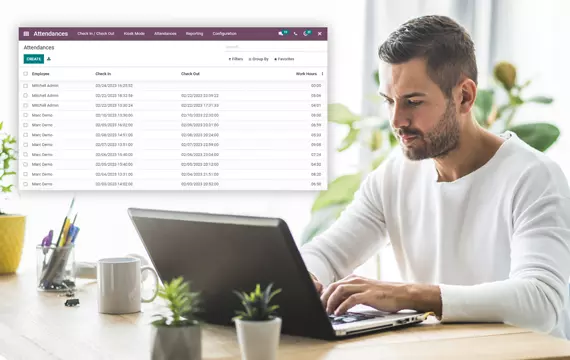

Barcode Scanner

Barcodes can help you move things along more swiftly at every level, whether you operate with quantities, serial numbers, or inexplicable goods:

- Regulating reception

- Selecting and packing orders for work

- Among other things!

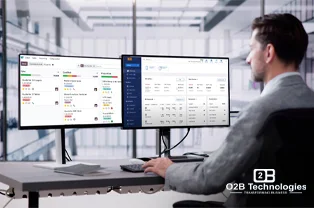

O2b Technologies for Manufacturing

O2b Technologies can help you to meet the challenges by providing “Odoo” an efficient and cost-effective Open Source ERP solution that helps manage all aspects of your business. It has a modular approach so as per requirement you can go for the required module. Likewise, we have an MRP module for the Manufacturing sector. First, we will inherit the Odoo MRP operations because this module is fully responsible for adding the Manufacturing order operation that totally depends on Routing configured on BoM.

.webp)

USA

USA INDIA

INDIA