Odoo ERP manufacturing software helps in managing and tracking all manufacturing operations which ultimately helps the decision makers to gather the complete information in just a few clicks and better decisions result in better business growth.

Odoo ERP manufacturing software is helpful in the improvement of scheduling and planning on-time delivery of products, better demand planning. Companies that are engaged in mass production, and manufacturers have a large amount of stock inventory incoming and outgoing for production. Odoo ERP manufacturing software manages and tracks all the inventory records like location, number of units, and more.

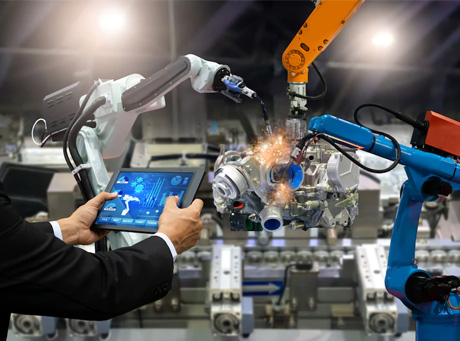

Before the manufacturing process, routing needs to be properly done. Routing is the method of product creation by making use of materials defined in the BOM. It might include multiple stages with work centres. The Odoo manufacturing ERP software executes the following:

The Odoo manufacturing software examines quality checks for purchased materials before production, in the middle of manufacturing stages, or as final inspections. On account of any challenges, the quality check systems in Odoo manufacturing ERP software help remove the issue, ultimately improving product quality and customer satisfaction.

The Odoo ERP manufacturing also allows maintenance orders for repairs. These orders are assigned to the maintenance team by organizing requests. This allows these systems to automate preventive maintenance by computing statistics like average time to failure.

The actual location in a manufacturing company where various manufacturing processes are carried out is called the work center. The user can do route-based production and specify the details of the work center in Odoo manufacturing ERP software.

The Odoo manufacturing software provides a detailed analysis report of the production line, analyzes the performance of your work centres and production, plans alternative production strategies, etc. These are some of the qualitative measures that the O2b BI engine provides in the Odoo ERP manufacturing module.

This solution will provide an understanding of the manufacturing functioning of the company and its direction of operations based on the data available. Hence, Odoo manufacturing ERP software improves decision-making and overall business performance.

O2b’s manufacturing solution easily integrates with other departments and increases the transparency and clarity among the different divisions on a single platform. It gets integrated with verticals like:

Inventory software for manufacturing helps you to know the accurate history of your stock operations. The manufacturing industry can adjust inventory in real-time because of the live tracking feature of our system.

CRM in the manufacturing sector helps to get customers’ contact information for planning and analysis of operations of the production department. Our best CRM for manufacturing business sends confirmed customer orders to the production and now you can track all the sales orders from the quotation to delivery.

With our purchase management software manage purchase orders with a single click. Automate the entire procure-to-pay process easily and flawlessly. This system helps you to get approvals and expense reports easily by automating the whole purchase process.

O2b Technologies’ Odoo manufacturing software is a great fit for a wide range of industries such as textile, electronics, food and beverage, industrial machinery and equipment, medical device, and furniture. Odoo manufacturing ERP software can manage these manufacturing industries regardless of their type of manufacturing. These types are, assemble-to-order, batch, discrete, make-to-order, and make-to-stock manufacturing.

O2b Technologies also provide Odoo ERP manufacturing software for small businesses which indicates there is no barrier to the budget in investing in Odoo manufacturing software solution.

Choosing O2b Technologies for your Odoo manufacturing ERP software solution provider gives you the chance to get the solution team to have expertise in the domain and years of experience in providing the best Odoo ERP manufacturing software for the manufacturing business.

O2b technologies has a solution available for every Industry, addressing the specific needs and challenges faced by businesses within those sectors.

The cost depends upon the consultant’s fees and the selection of functionalities in the modules in case, you are opting the customization.

Yes, we can.

Yes, you can with the assistance of our quality team.

Yes, there is.