Latest Manufacturing Industry Trends

ERP is an integrated business management system that provides the transformation for manufacturing industries from their traditional software system. As a matter of fact, we know that today’s business environment is vicious and it becomes very necessary to be prepared to face the competitive market worldwide. An ERP software provides the solutions that empower manufacturing industries to gain more competitive advantage. With this in mind that the business environment is changing drastically because of continuous advancement in technology. Most of the industries are going through the transformation phase. such as electronics, food and beverage, textile, industrial machinery and equipment, medical device, and pharmaceutical are also transforming with technology. An ERP system is continuously helping the manufacturing sector in transforming as well as for technological advancement. The growth of any industry depends on how they are transforming with the latest technology.

When the ERP system was at its initial phase in the 1990s, it majorly serves manufacturing industries for manufacturing resource planning (MRP). After that ERP continuously offering its benefits to the manufacturing sector. Manufacturing Industry 2020 trends are driven ERP system that enhances the manufacturer’s confidence about their ability. In this highly competitive world, they are focusing on delivering high-quality products. That enables them to repeat orders while delivering magnificent customer experiences.

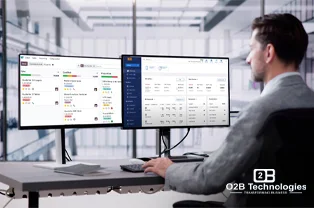

We are now in 2023 and manufacturers are looking forward to gaining significant insights from the enormous amount of data they produce to make shop floor operations more effective and become more competitive. Equally important, intelligent analytics and Business Intelligent applications aids in managing performance bars and the capabilities to improve shop floor productivity. ERP software is helping manufacturing industries with the evolution of digital technology, globalized partnership opportunities, and increasing need for competitive advantage.

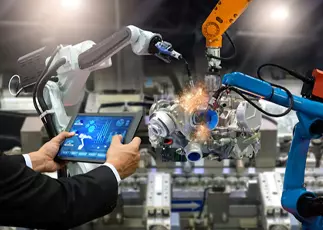

Automation

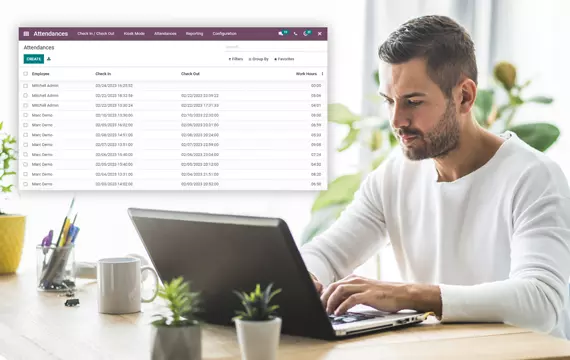

ERP software enables the management of your manufacturing processes in a more effective and better way. As a result, it helps to transform the supply chain management process by integrating it to the production, sales, CRM, and finance. The integration of manufacturing management software helps to achieve a production plan with your sales plan, finance management, and customers. The first thing to remember, automation has always been a significant part of the manufacturing sector. With this in mind that ERP software primarily utilized in the core mechanized processes of this industry. This software solution allows the automation of different functions of a business. For successful automation, manufacturing unit needs various software solutions like Finance management, order processing, purchase management, CRM, vendor management, and human resource management.

Outsourcing

The manufacturers continuously seeking ways that improve their operational efficiency. It has been observed that outsourcing in the manufacturing industry comes into the trend in 2016. In this case, it shows the perfect way to improve their operational efficiency. Furthermore, manufacturers are looking to expand more rapidly but they unable to do so using their internal resources. For global expansion and to improve their core competencies, outsourcing is the best solution. More outsourcing and leasing of non-core functions and services such as parts manufacture, maintenance, benefits management, and payroll services definitely improve operational efficiency. Equally important, by outsourcing these functions, the manufacturers are able to concentrate on the manufacturing process only. It may sound easy, outsourcing, but providing all the required data for this outsourcing process is not an easy task. Although this may be true, instead of this an ERP system has the solution to this outsourcing issue.

Globalized Manufacturing

The improved technology and streamlined global logistics made the supply chain process free from any kind of limitations caused by geography. Now there is no reason that you are unable to find customers or suppliers all around the world. It has never been simpler, faster, or cheaper than it is in the current business environment to move information and products from one place to another. Now the manufacturers are unable to send their products to various countries without any kind of hurdle. Synchronization of data becomes more convenient and easier because of Cloud ERP. To put it differently, from a single location now you can operate your business all around the globe. Another key point, in today’s business environment the companies are now able to deploy their business worldwide flawlessly.

Reduce Costs

A robust ERP software has the ability to streamline and automate business management processes that make sure to decrease administrative and operating costs. Definitely, reduced operational cost maximizes workflow efficiency. As we know that it also enhances workforce productivity, reduces labor costs hurdles and delays. The ability to track inventory accurately and integrating it more effectively with production planning avoids excess inventory and warehousing costs. It also improves visibility across the organization, which surely helps them to save more operational costs. ERP solution facilitates better production planning, streamlining processes, improved control over inventory and it enables on-time product delivery. Important to realize, delivering products at the right time is necessary to maintain customer satisfaction.

.webp)

USA

USA INDIA

INDIA