.jpg)

How Manufacturing Software Solutions Are Transforming Modern Industries

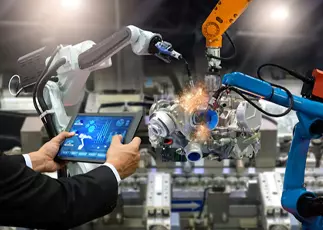

In the moment's largely competitive artificial geography, manufacturers are under constant pressure to enhance effectiveness, reduce waste, maintain quality, and meet ever-growing client prospects. To survive and thrive in this terrain, companies are turning to manufacturing software results, comprehensive tools that streamline operations, increase visibility, and enable data-driven decision- timber.

Whether you're a small company or a global enterprise, investing in the right software can significantly impact your bottom line. In this blog, we will explore how manufacturing software solutions are revolutionizing the industry, their crucial features, benefits, and how O2b Technologies helps businesses apply these results effectively.

The Evolving Need for Manufacturing Software

Traditionally, numerous manufacturers relied on spreadsheets, paper records, and disconnected systems. While this approach worked in history, it no longer meets the demands of Industry 4.0. With growing force chain complications, demand for customization, and rising labor costs, businesses need real-time data and robotization to stay competitive.

Manufacturing software solutions help bridge the gap between the shop bottom and the top bottom. They empower manufacturers to plan better, allocate coffers efficiently, reduce time-out, and produce high-quality products constantly.

Benefits of Using Manufacturing Software Solutions

Here are the top advantages companies witness when adopting manufacturing software:

Improved Production Efficiency

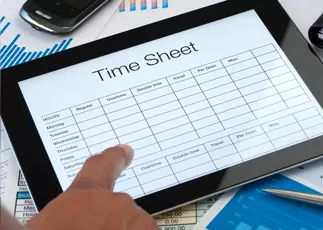

Automated scheduling, resource planning, and real-time monitoring reduce product detainments and optimize machine application. This helps manufacturers produce further in less time without compromising quality.

Real-Time Data and Analytics

Access to real-time data allows directors to identify backups quickly, make informed opinions, and respond to changes in demand or force immediately.

Reduced functional Costs

Robotization and optimized workflows lead to a reduction in homemade errors, waste, and rework. By perfecting delicacy and process control, software results can significantly lower overall functional costs.

Enhanced Quality Control

With erected-in quality checks and compliance shadowing, manufacturers can ensure that products meet specifications and nonsupervisory norms. This leads to smaller blights and advanced client satisfaction.

More Inventory Management

Manufacturing software can track force situations, manage reorder points, and minimize overstock or stockouts. This leads to better cash inflow operations and lower capital tied up in force.

Integration Across Departments

From procurement to deals, and from product to account, manufacturing software connects all departments on a single platform. This promotes better communication, translucency, and alignment of business pretensions.

.jpg)

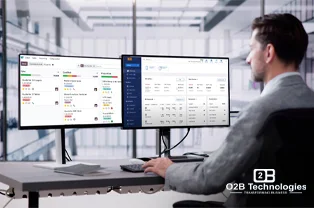

Why Choose O2b Technologies for Manufacturing Software Solutions?

At O2b Technologies, we specialize in delivering knitter-made manufacturing software results that fit your specific business requirements. With times of experience across colorful diligence, our team understands the unique challenges manufacturers face and how to break them with technology.

That’s why manufacturers around the world trust O2b Technologies

Customizable results

We understand that no two manufacturing operations are likewise. Our results are completely customizable, allowing you to elect the features and modules that match your workflows and conditions.

Industry moxie

From automotive to medicinals, our team has enforced manufacturing software across a broad spectrum of industries. This gives us the capability to anticipate challenges and offer stylish practices that align with your pretensions.

End-to-End perpetration

We don’t just sell software. We match with you from the original discussion and system design to deployment, training, and ongoing support.

Scalable Platforms

Our results grow with your business. Whether you are expanding operations, entering new requests, or adding product lines, O2b’s software platforms can adapt accordingly.

Pall and On-Premise Options

We offer both pall-grounded and off-premises deployments, depending on your preferences and IT structure.

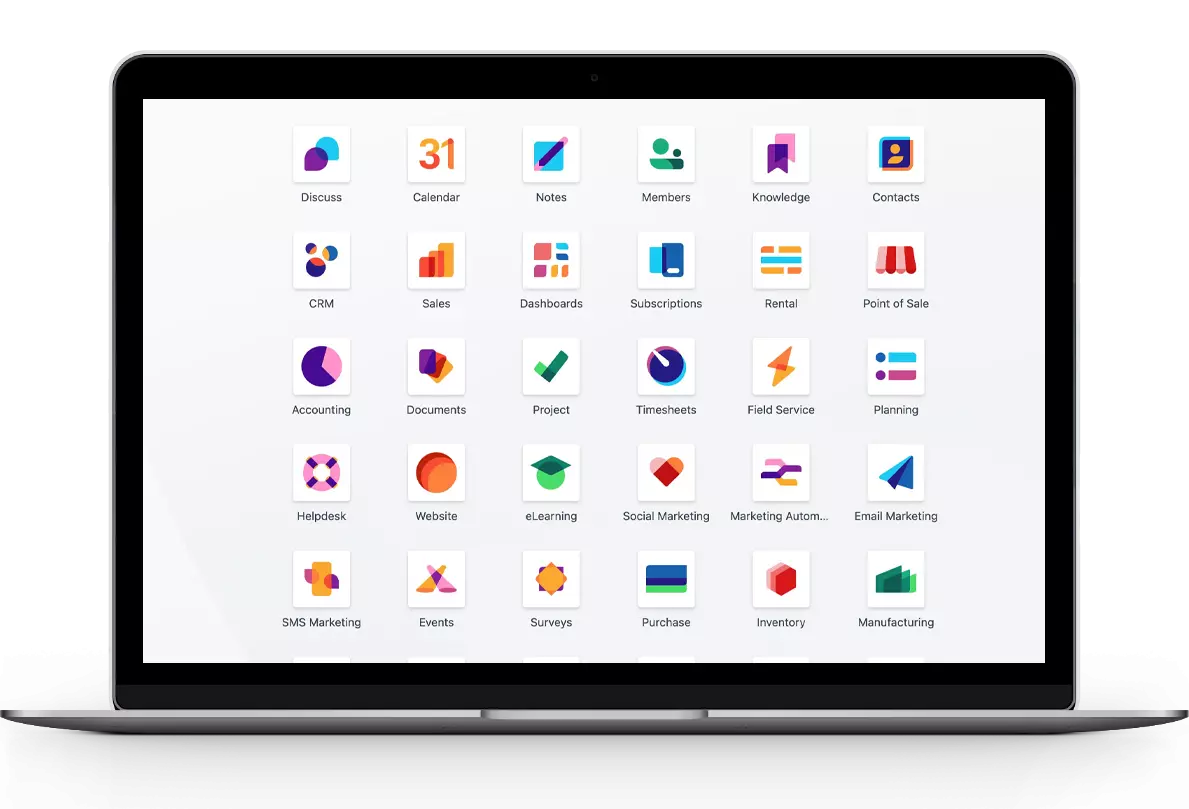

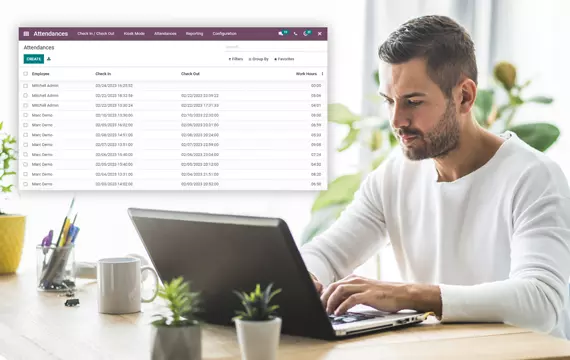

Crucial Features of O2b’s Manufacturing Software Solutions

Then’s a shot of the critical features included in O2b’s manufacturing suite

These features ensure that your manufacturing process is flawless, data-driven, and aligned with your strategic pretensions.

.webp)

USA

USA INDIA

INDIA